Pumping stations

The service life and efficiency of a pump depend primarily on the overall hydraulic design of the pumping station in which it is installed.

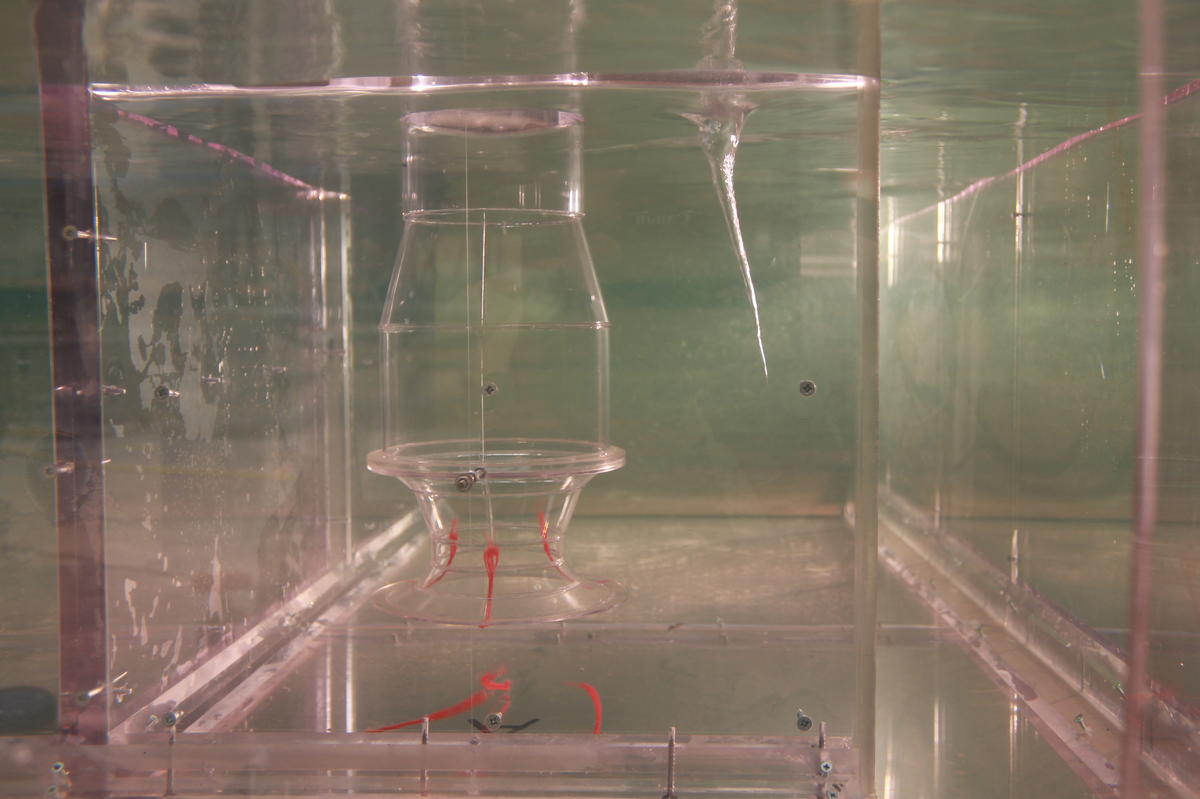

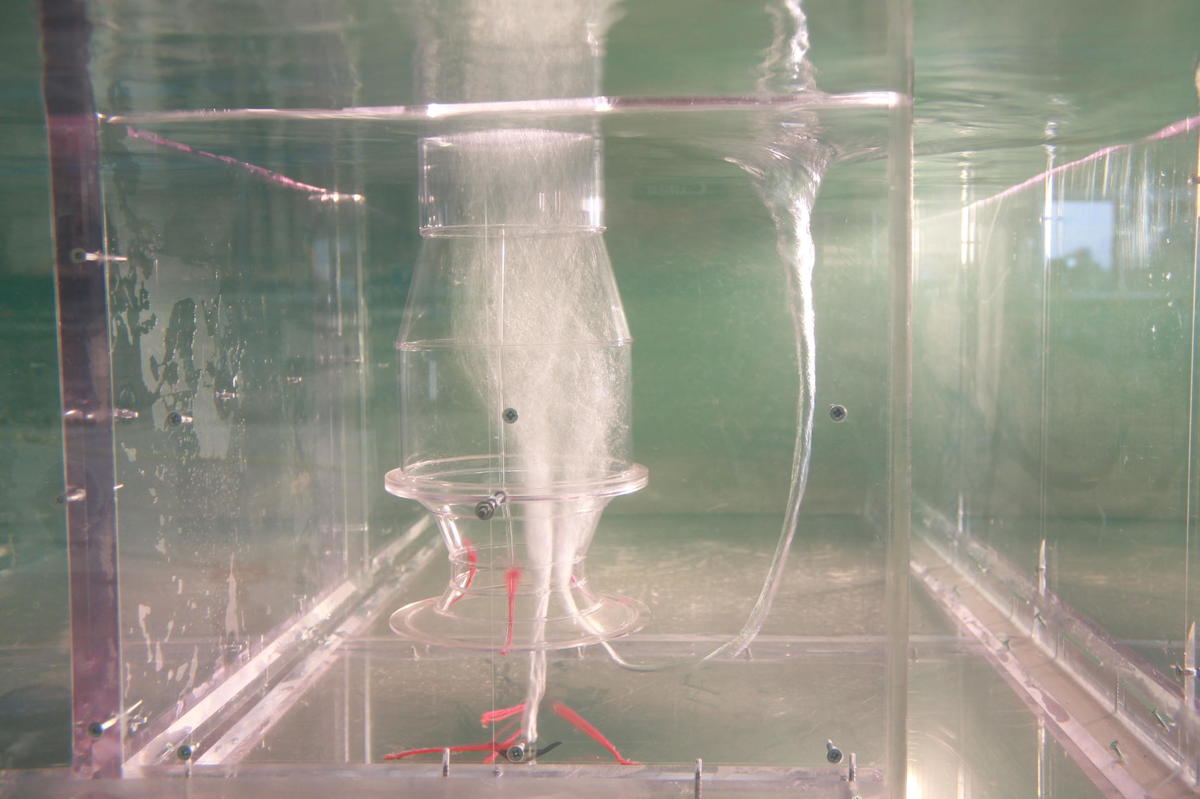

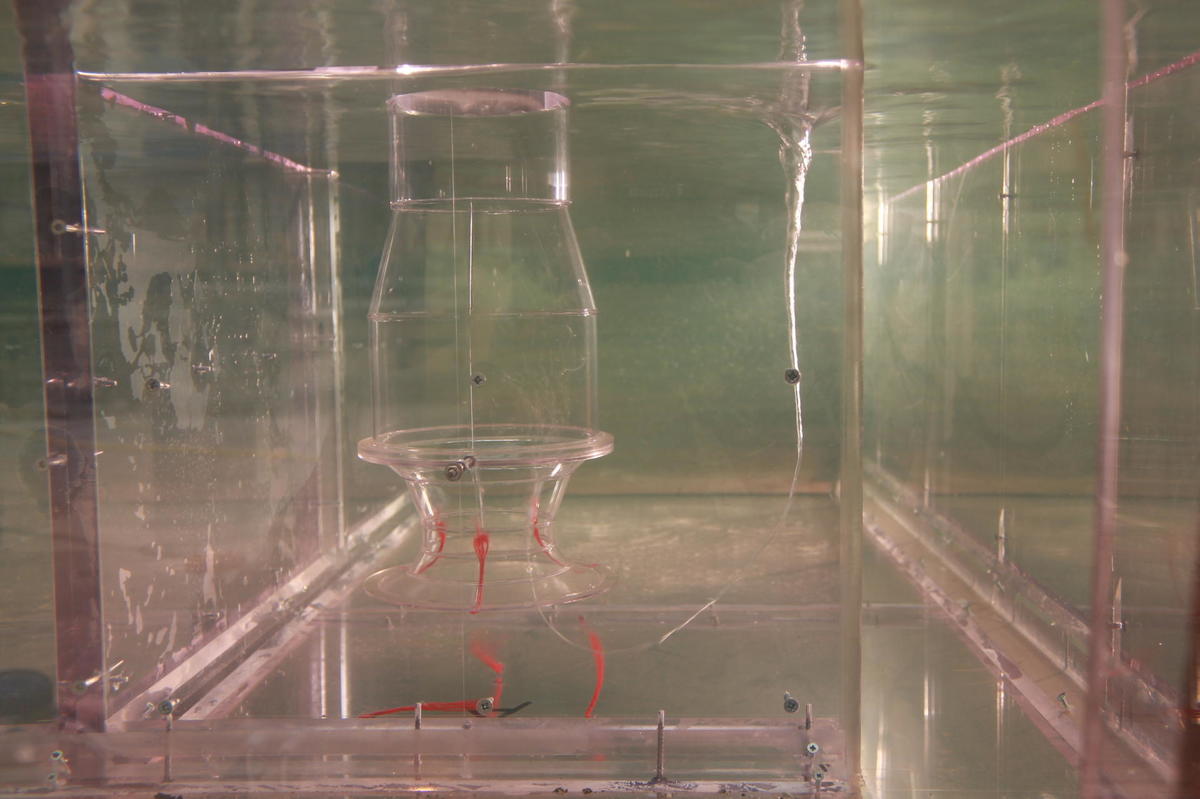

When it comes to accurately representing fast, fluctuating 3D flows, physical modelling is still unquestionably the benchmark technique.

What we do

Whether they involve raw water, stormwater, wastewater or salt water, pumping projects are always a challenge from the hydraulic design standpoint. Special attention must be paid to the approach conditions before the pumps - from the screens to the bellmouths - to ensure that the velocity field remains uniform and free of disturbance and rotation in all operating conditions. And yet flows can change radically from one set of conditions to another, such as following the closure of a screening line, a slight difference in water level or the shutdown of a pump.

If these stringent hydraulic conditions are not met, the design of the pump propeller or impeller may no longer be appropriate, and this could have serious consequences for the equipment: vibrations, a drop in efficiency, excess electricity consumption, flow separation, cavitation, significantly reduced service life, etc.

Physical modelling is a powerful tool for addressing these issues and has been the benchmark in pump engineering for many years. It is still required today by the ANSI/Hydraulic Institute standard 9.8 to guarantee the design of any new project. Artelia’s modelling services can:

- accurately reproduce flows in the future structure,

- perform tests with a wide range of operating conditions,

- visualise, understand and analyse flows,

- assess the sensitivity of flows to any of a large number of hydraulic parameters such as flow rate, water level, number of pumps operating, number of bar screens operating, etc.

- propose corrective solutions and confirm their effectiveness.

Whether Artelia is commissioned to design the pumping station or simply to model it, the laboratory’s task hence consists in assessing the hydraulic efficiency and robustness of the design and taking any steps required to optimise it in order to guarantee a long pump service life and high efficiency.

Our expertise

Drawing on its wealth of experience in the physical modelling of pumping structures, Artelia’s laboratory develops and studies models while taking particular care to comply with best engineering practice and international standards (especially ANSI 9.8). We undertake in particular to:

- produce a design that guarantees excellent similitude with the prototype structure (choice of scale, footprint, materials, boundary conditions),

- operate the model using a wide range of hydraulic conditions, from typical cases to exceptional cases,

- comply with the criteria laid down by standards in the profession,

- take detailed measurements to qualify and quantify:

- flow rates and flow velocities,

- head losses and water level profiles,

- the pre-rotation angle in the pump impeller, and variations over time,

- velocity distribution in the pump inlet section, and variations over time.

- analyse the observations and measurements in detail, and make concrete recommendations to optimise the structure.