Lock gate sealing system

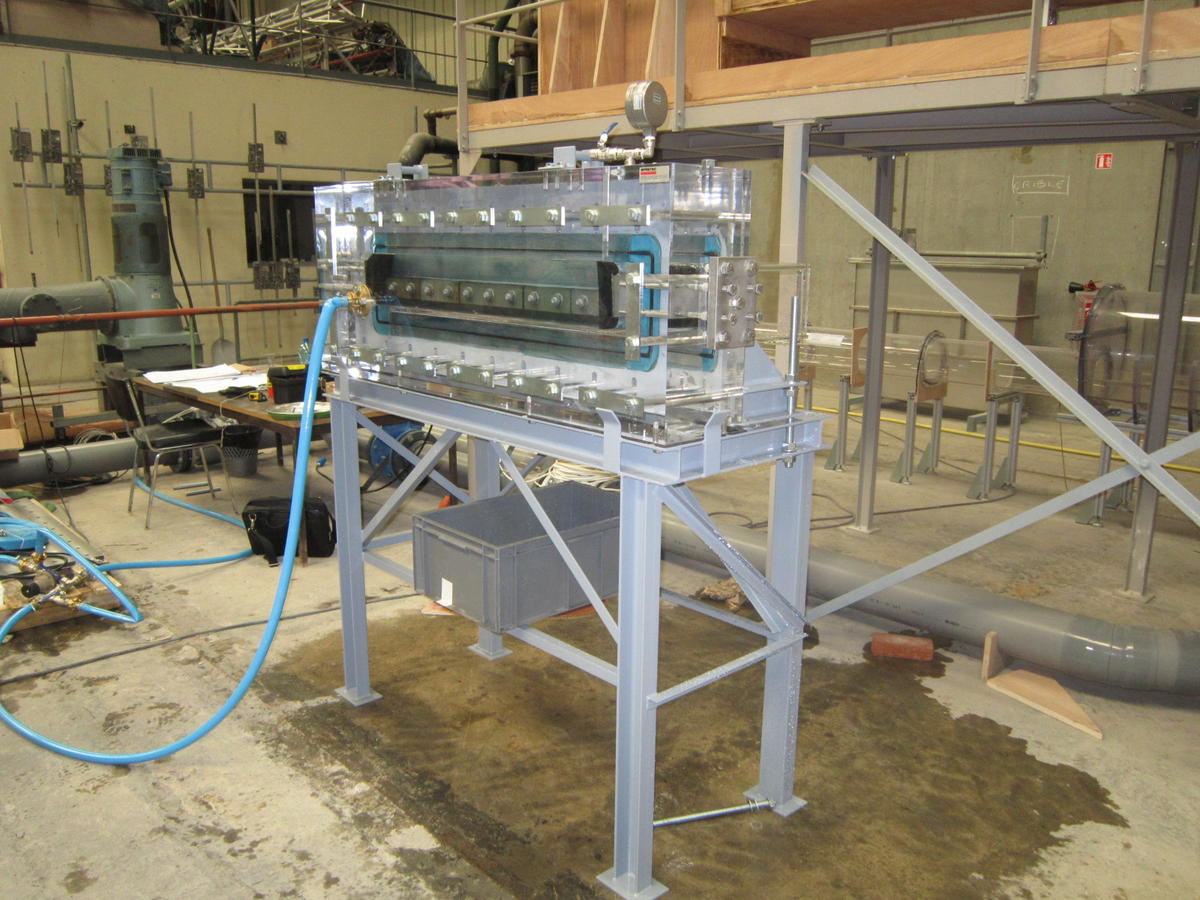

Testing a new lock gate sealing system at Artelia’s Laboratory

Background to the tests

Seals on the gates of Bollène and Châteauneuf locks - Compagnie Nationale du Rhône (CNR)

In the context of a study being performed by Artelia Group company Spretec on behalf of the Compagnie Nationale du Rhône (CNR), a test bench was set up at the laboratory near Grenoble with the aim of improving the seals on the downstream gates of Bollène and Châteauneuf locks.

Up to now, the sealing systems on the gates of the two locks have consisted mainly of a simple rubber corner seal fitted to the lower part of the gate skin plate, supported horizontally by a section embedded in the floor. With this type of corner seal, there is a risk of it overturning if the small gap between the gate and the floor is allowed to become too large, owing to the pressure or the flow rate - even if it is low - between the upstream and downstream sides.

But this gap cannot be kept small on gates of this size for a number of reasons including expansion, the length of the operating chains, and the level of end stop precision.

Information provided by the tests

The test bench built by Spretec was used to test a new sealing system design that can tolerate a much larger gap, the gate being safely stopped earlier in its descent.

Complementing the current principle, a flexible steel blade is inserted into the gap between the gate and the floor. This blade serves as a vertical support for the rubber joint, preventing it from overturning under the effect of pressure and/or residual flow. Since the blade is flexible, it can be crushed in the event that the gap shrinks for any of the reasons mentioned above.

Given the innovative nature of this principle, tests at actual size were indispensable. A glazed test bench enabling a mobile component (the gate) to move under hydrostatic pressure on a fixed base (the floor) provided a means of assessing the assembly’s behaviour with different gap sizes.

The results made it possible to validate the new sealing principle for these lock gates of exceptional size, which provide passage for several dozens of boats per day.