Stormwater outfall pumping station in Dubai

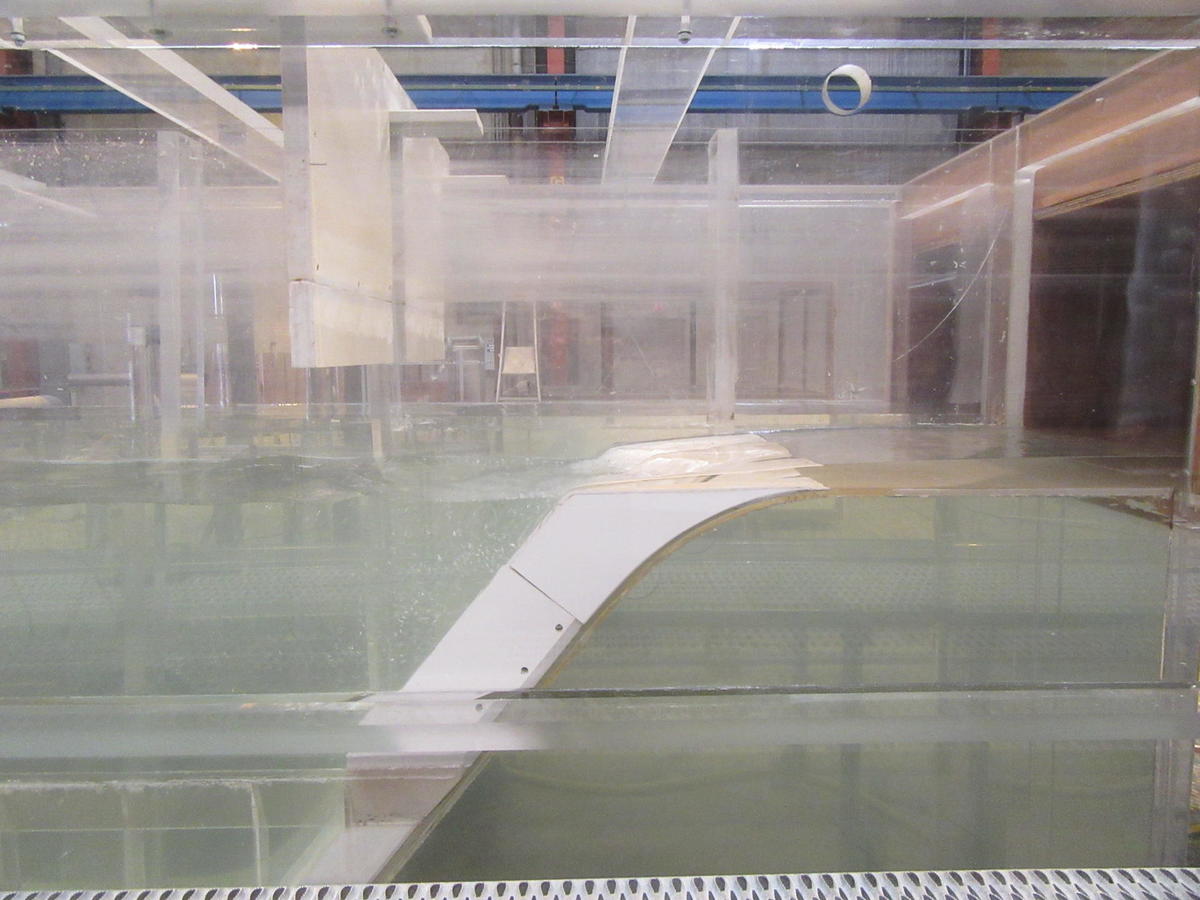

In the framework of development of the stormwater network in Dubai (UAE), the final pumping station (before water is discharged into the sea) was studied on a physical model at Artelia’s laboratory.

Context

Stormwater drainage tunnel at Dubai pumping station (UAE) - Client: ARCHIRODON - Dubai Municipality - Scale: 1:10

This structure is exceptional in terms of its geometrical dimensions and its colossal flow capacity (up to 36 m3/s), making it a vital component of the new stormwater management scheme implemented by Dubai Municipality.

A physical model study to check and validate its hydraulic design was essential in order to ensure that it would operate correctly during the intense rainfall episodes that can occur in the Middle East. To ensure optimal performance, the four large-capacity (DN 1800) vertical pumps must be supplied with a uniform, non-rotating velocity field for all configurations of the various parameters (ingoing flow rate, stoplog opening, water level in the pumping station, etc.).

Crucial hydraulic parameters studied on the model

The physical model was used to characterise the hydraulic behaviour of the structure in all possible operating conditions, both frequent and rare, including in particular:

- characterisation of the 3D velocity field in the approach structures before the pump bay,

- observation of the formation of surface and subsurface vortices, their intensity and their stability,

- detailed measurement of pre-rotation in the flow at the intake of each pump,

- velocity distribution at the inlet of each pump (using Pitot tubes and differential pressure sensors), in order to detect and quantify any risk of unbalanced distribution,

- the formation of air bubbles and risk of air entrainment at the intakes of the pumps and the discharge system.